Engineers have made the perovskite layer transparent and better transmit infrared rays.

The Japanese company EneCoat Technologies announced the creation of a four-contact tandem solar cell based on perovskite and silicon with an efficiency of 30.4% in partnership with Toyota Motor Corporation Ltd. It posted the details on its official website.

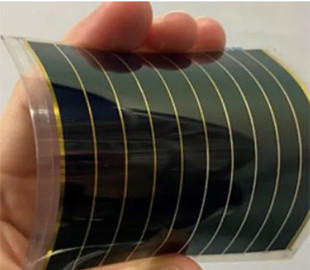

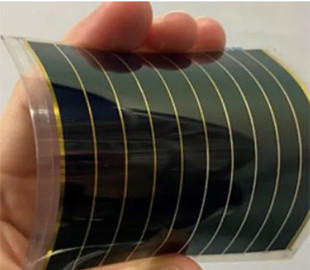

The tandem cell uses a flexible perovskite top cell with an efficiency of 22.4% and an infrared transmittance of 81%, as well as a mysterious crystalline silicon solar technology for the bottom device, which the developer has not yet disclosed. This is an extremely high figure for transparent-type solar cells, which has not been recorded anywhere else in the world. The company did not specify whether the result was confirmed by an independent third-party organization, but hinted that the new panels are planned to be placed on the roofs of cars.

“The conversion efficiency values obtained during this development were measured on a small area at the cell level, and we will continue to develop large-scale solar cell modules to achieve practical applications of high-efficiency solar cells that will benefit users,” EneCoat Technologies added.

Solar cells used in cars, satellites and other applications must have the highest possible conversion efficiency due to the limited area available for their installation. Theoretically, the maximum energy conversion efficiency of perovskite cells is 33.7%, and tandem cells, which are made by combining perovskite and crystalline silicon cells, are 43.8%. The structure of tandem solar cells involves separate layers of perovskite and silicon arranged in the order of light reception. The perovskite cell in the foreground absorbs the visible spectrum and transmits the infrared region, which is then captured by the silicon.

A perovskite solar cell generates electricity first, so it must be able to both generate energy well from visible light and transmit infrared rays further without loss. This time, both companies focused on the throughput of perovskite and significantly increased it.

The conversion efficiency was measured on a small area of the solar cell, but in the future, EneCoat promises to make a large-sized module that can be used in practice. The results will be presented at the Asia-Pacific International Conference on Perovskites, Organic Photovoltaics and Optoelectronics (IPEROP25), which will be held on January 21 and 22, 2025 at Kyoto University's Uji Campus.

EneCoat is developing a number of applications for its thin-film perovskite technology, which it manufactures using a proprietary low-temperature deposition process, such as applications that require high efficiency in low light conditions, as well as outdoor photovoltaic installations that require lightweight and flexible solar panels. As of March 2023, its modules had an efficiency of 19.4%, according to PV Magazine.