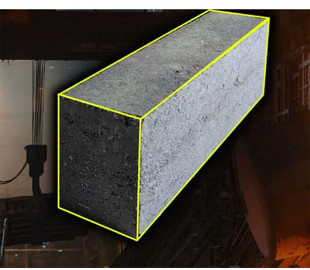

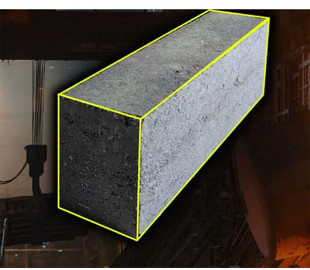

Scientists at the Massachusetts Institute of Technology (MIT) have developed an electrically conductive refractory brick that can store heat up to 1800°C, which could replace fossil fuels in manufacturing processes and make the industry more environmentally friendly.

Most industries, such as cement, steel or chemicals, depend on high-temperature heat, which is usually obtained by burning fossil fuels, which are a major source of carbon emissions. In response to this problem, a startup called Electrified Thermal Solutions, created by MIT engineers, has proposed a system based on conductive refractory bricks. In the basic configuration, the system is capable of storing 25 MW·h of thermal energy and generating up to 5 MW of power, replacing fossil fuels with energy from renewable sources.

The basis of the development was traditional refractory bricks – a cheap material historically used in stoves and fireplaces. The innovation lies in modifying its chemical composition, which turns the material into an electrically conductive one. Such bricks are heated by electric current, and not by additional heating elements, which are unreliable and limited in use. At the same time, the characteristics of the new bricks are 98% similar to standard analogues, which makes their production affordable and compatible with existing technologies.

Conductive bricks can heat gases or air to the temperatures required for the most complex industrial processes, including steel, cement, glass, paper and food production. Their efficiency is particularly evident during periods of peak electricity generation from renewable sources, allowing excess electricity to be used to heat the bricks and subsequently – to supply heat to production.

The system, based on conductive bricks, is integrated into standard metal containers with thermal insulation. It can adapt to various industrial tasks, providing environmentally friendly heat where it is needed. Due to its simplicity and versatility, the technology has attracted the attention of industrial giants, and has also received support from the US Department of Energy, which has invested $40 million to develop a commercial version of the megawatt-scale system.

Despite significant progress, the key advantage of this development is its ability to integrate into existing enterprise infrastructure, facilitating the transition to green technologies. The first commercial systems are expected to be operational within a few months, demonstrating the potential to reduce carbon footprints in important sectors of the economy.

The use of electrically conductive refractory bricks could be a turning point in the global decarbonization of industry. This solution helps to combine economic efficiency with environmental sustainability, paving the way for the use of renewable energy sources in large-scale production processes.