A new industry is actively developing in Ukraine – drone production. This has become a critically important direction in war conditions, as drones play almost the main role in reconnaissance, fire control, strike operations and logistics.

In recent years, many Ukrainian companies have emerged that create drones for various purposes – from FPV strike to reconnaissance models. Local developers are actively improving their technologies, introducing innovations, analyzing the enemy's experience and adapting to the conditions of modern combat. Among the new interesting technologies – drones controlled via optical fiber, which makes it impossible to be affected by enemy electronic warfare. Despite significant progress, manufacturers face challenges – from bureaucratic procedures in government procurement to competition with foreign manufacturers. At the same time, the government and private initiatives stimulate the development of the industry through funding programs, grants and orders for the Armed Forces of Ukraine.

One of the developers of fiber-optic drones is the Ukrainian company 3DTech, which presented a new drone to the press at a presentation in February. 24 The channel visited the presentation and talks about the latest developments and problems in the industry.

Fiber-optic drones: why they are so unique

Fiber-optic drones – are drones that use wired communication via optical fiber instead of traditional radio channels.

This technology has several key advantages:

- protection against electronic warfare (EW) – due to the lack of a radio signal, they cannot be silenced or intercepted, which makes such drones especially valuable in modern electronic warfare;

- stable communication and low latency – data transmission via fiber optic is fast and without loss of quality, which is especially important for reconnaissance missions;

- high security – the enemy cannot determine the location of the operator by the drone signal, which reduces the risk of attacks on the command post.

Despite the obvious advantages, fiber-optic drones also have certain limitations. For example, the range depends on the length of the cable, which limits mobility compared to radio-controlled UAVs. There is a threat of vulnerability of the cable itself – in combat conditions it can be cut or damaged, which will disable the drone.

There is also a need for special reels and mechanisms for winding fiber optics – this increases the weight and cost of the system.

In Ukraine, several companies, including 3DTech, are working to improve fiber-optic drones, taking into account the enemy's experience and improving the design of the coils to increase the flight range. Such drones can become an effective solution for reconnaissance and fire correction in conditions of severe electronic warfare. Due to the rapid development of technology, fiber-optic drones have the potential to become an important component of modern warfare and gain wider application in the future.

How 3DTech was created

The 3DTech company was founded by Oleksiy Zhulinsky, who, after being seriously injured while serving in the Armed Forces of Ukraine, decided to help the military by creating unmanned aerial vehicles. In 2023, the company delivered the first “Predator EOBOff” drones for the Ukrainian army.

The company's CEO Roman Agarkov in a comment 24 Channel previously noted that bureaucratic obstacles and corruption in tender procedures forced 3DTech to cooperate with the military directly. He also emphasized that the low prices of imported drones make them profitable for the state, but this is too low a threshold for local manufacturers.

The company is actively analyzing the experience of the enemy to improve its own developments, in particular fiber-optic drones. They took into account the larger supply of coils in Russian drones and adapted this in their models.

We have been working on this technology for four months, and all this time the drone was just sitting in our office – no one needed it. But when the Russians in the Sumy direction began to massively destroy our equipment, a real need for such a solution arose. We realized that we needed to develop this direction, since the front is saturated with electronic warfare means. Our drone is able to bypass this protection. And, unfortunately, the enemy began to massively use such technologies before us. Frankly speaking, we learned a lot from the enemy drones that the Prytula Foundation transferred to us. We adopted some technological solutions from the Russians, because they have more experience in this, – said 3DTech CEO Roman Agarkov.

According to him, the codification process will probably last several more weeks. If the drones successfully pass the acceptance procedure and a production contract is signed, 3DTech will be able to produce up to 7 thousand fiber-optic UAVs per month.

Currently, the company manufactures drones exclusively for specific orders from volunteers, military and charitable foundations, and the volume of such production does not exceed 500 – 600 units per month.

What drones does the company manufacture: characteristics

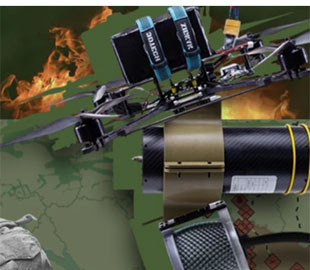

3DTech introduced a new line of fiber-optic drones in February. According to CEO Alexei Zhulinsky, the drone line has expanded and consists of drones on 10- and 13-inch frames, which differ in range and payload.

- Range – 12, 15, 20, 25 kilometers.

- Warhead weight – from 1.5 to 3.5 kilograms.

- It is also planned to release a drone with a range of up to 40 kilometers.

- The flight duration of such drones is up to 30 minutes, the maximum speed is up to 130 km/h, as tests have shown.

The company has also improved the coil mounting system. Zhulinsky noted that the new drone form factor is designed so that the coil nozzles do not interfere with the propellers, which improves maneuverability. Thanks to this, the drone can freely change its trajectory, approach the target and fly around it without the risk of hitting the coil.

In addition to the drones themselves, 3DTech has improved the ground control stations. They are presented in three versions depending on the type of coils.

“We made them in airtight boxes so that they are convenient to transport and use in any weather conditions”, – Zhulinsky said.

A feature of the ground stations is the signal relay system, which allows the operator to work both via cable and wirelessly, completely avoiding the use of radio frequencies. The cable length can reach 100 meters.

The company also updates the ground stations every week, based on feedback from the military.

We receive feedback from the Armed Forces of Ukraine and are constantly improving the design,

– Zhulinsky added.

Fiber-optic drones are more expensive than traditional drones, as their design uses special coils and media converters. At the same time, 3DTech is working to reduce the cost and make them more accessible to the military.

“We started our own production of coils to localize production and reduce costs,” Zhulinsky added. According to him, the company is constantly looking for more affordable and secure media converters to reduce dependence on Chinese suppliers. Negotiations are currently underway with Germany regarding alternative sources of material supply.

3DTech also seeks to use Ukrainian components as much as possible.

There are more and more manufacturers, although the quality does not always meet our requirements. But the situation is improving, and we are constantly testing Ukrainian components,

– the company's head said.

The company reported that 3DTech has already passed the tests of the codification commission and is now waiting for the signing of acts. This will allow purchasing drones through the state budget.

“We are waiting for the final documents, and in a week we can ship drones under the contract,” – Zhulinsky concluded.

Is it difficult to control a drone on fiber optics

3DTech chief engineer and combat pilot Oleksiy explains that fiber-optic drones do not require a radically new approach to control, but they do require more accuracy. He notes that sharp maneuvers are undesirable, as the cable can stretch or get tangled, but overall the control is intuitive and the response is instant, without any delays.

Regarding flights in difficult conditions, for example, in the forest, Oleksiy admits that dense thickets make maneuvering difficult, but with proper pilot skills it is quite possible. It is important to correctly assess the dimensions of the drone and its sailability.

One of the main points is the location of the cable unwinding system. Early versions had it too close to the propellers, which caused the cable to wind up and interfere with flight. Now the unwinding point has been moved as far to the side as possible, which significantly improves maneuverability and makes it possible to perform complex figures in the air.

The team also adapts the control system for each drone. For example, for models weighing 2.5 kilograms and coils for 10 kilometers, it is important to adjust the current consumption in the Betaflight firmware to optimize the drone's operation.

What are the nuances of fiber-optic drone production in Ukraine

3DTech uses Ukrainian machines despite the fact that Chinese ones are cheaper, Roman Agarkov, CEO of 3DTech, told Channel 24. According to him, you can visually notice the difference in the materials from which the machines are made – this is the quality of the metal, motors, and winding. Therefore, the company does not work on Chinese machines.

Ukrainian machines differ in material thickness and winding quality, they look more reliable. In addition, they work as efficiently at high speeds as they look. Thanks to this, we wind the coils quite quickly: a ten-kilometer coil is made in 15 minutes,

– says Agarkov.

The work is carried out using a conveyor belt method, the interlocutor explains: pigtails (connecting elements) are soldered to the coil, the detail is checked, the signal is traced, measurements are made, and all the main indicators are recorded on the coil itself.

In particular, three main parameters are recorded: coil length, signal distance, signal reflection coefficients.

Chinese machines are difficult to maintain. We chose Ukrainian ones not only because of their appearance, but also because they have service and a guarantee from Ukrainian engineers. If something happens – this is a serious problem, because stopping production is painful for business. But thanks to Ukrainian manufacturers, we have a quick response – either remote assistance or on-site engineers,

– explains Roman Agarkov.

In addition, it is difficult to find a common language with Chinese suppliers when ordering parts for drones.

“They treat all foreign customers the same – they don't care who pays, the main thing is that the money arrives in advance. If they are late with the order, they simply offer a discount on the next one”, – says Agarkov.

Regarding fiber optics – the global market is dominated by Chinese manufacturers – approximately 90% of products come from China. However, there are alternative suppliers – India, the USA and Germany.

Ukraine does not have its own fiber optics production. The main importers supply products from China.

“We are negotiating with Germany, although their fiber is 30% more expensive. But this is a strategic partner that will remain with us even if China refuses. India is more logistically complicated, so we are now focusing on Europe,” Agarkov noted.

Despite all the difficulties, the technology is actively developing. Companies are experimenting with improving the design to minimize shortcomings and increase maneuverability. Already, new versions of such drones are demonstrating remarkable efficiency, and operators are learning to perform amazing maneuvers on them. So the question is not whether it is worth developing this technology, but how quickly it will become widespread and accessible to the front.